We represent several manufacturers whose equipment does not fall within one of our other categories. This equipment includes dampers, environmental control, power generation and other types of equipment.

Other Process Equipment

-

Eductors and Ejectors

Eductors and Ejectors are venturi devices which use a high pressure “motive” fluid to boost the pressure of a “suction” fluid. These can be used for various applications, including pump priming, chemical dosing, and vacuum generation.

-

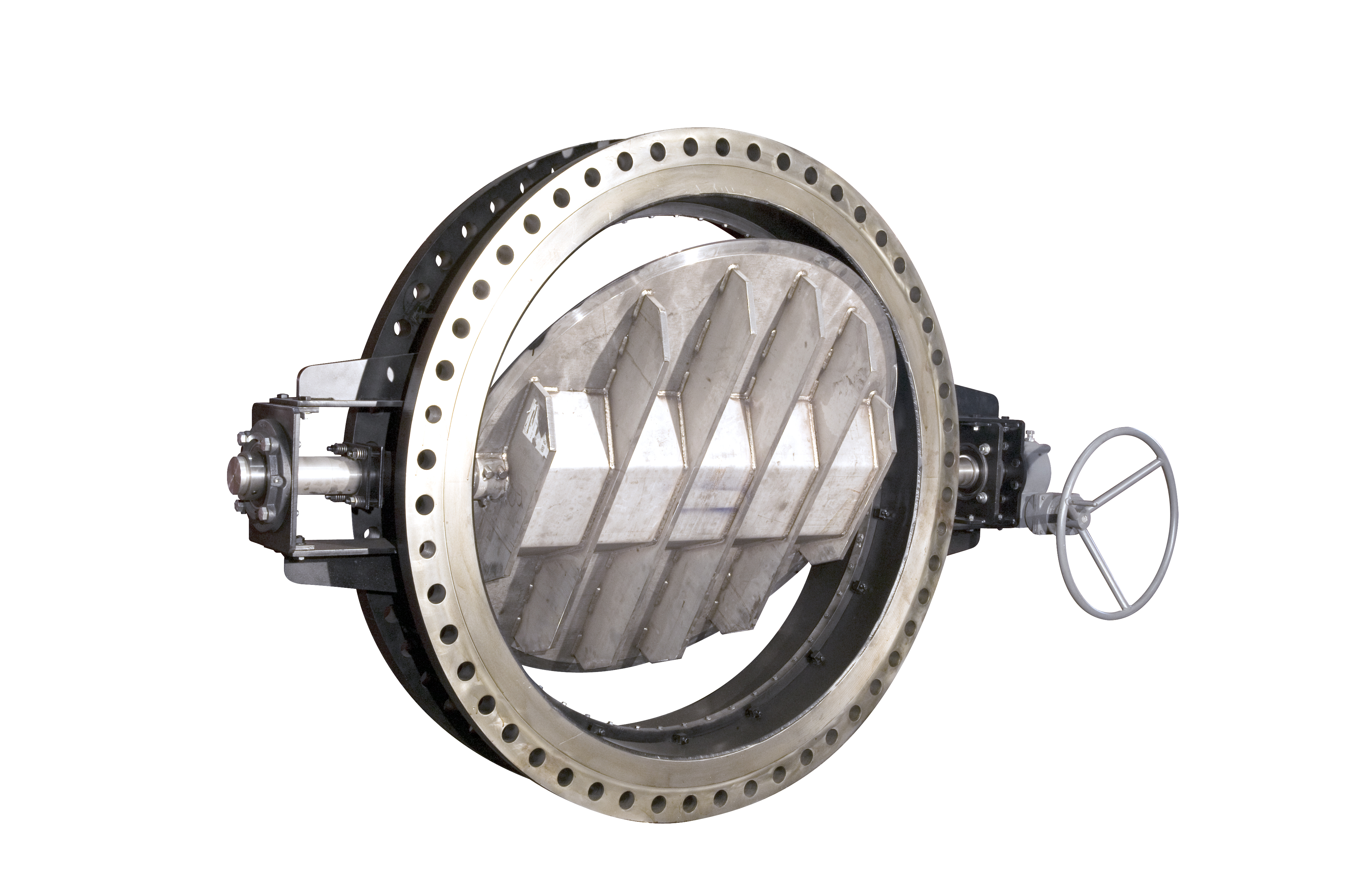

High Temperature Dampers

High Temperature Dampers are used for modulation of vapor flows in various types of applications. Typically, these applications are high temperature, located in waste heat recovery systems, boiler system, and heater systems. These modulating dampers use a butterfly valve configuration, and can be manufactured in various materials to enable use in these difficult services. In addition, they can be water cooled or refractory lined to protect the metal from extreme temperatures. For shutoff applications, we supply slide gate valves, which can also be manufactured to withstand the same extreme temperatures.

-

Wet and Dry Scrubbers

Scrubbers are used to remove pollutants from vapor streams. These scrubbers can either use a liquid medium or a dry medium for this removal. The liquid medium systems can consist of either a venturi scrubber, packed tower scrubber, or a combination of these. For the dry scrubber, the contaminated vapor flows through the solid media, which is often in the form of pellets which have been impregnated with a chemical to remove the contaminant.

-

Packaged Gensets and Noise Attenuation

For non-standard Genset applications, we can help. These applications can include several requirement which can be difficult for the engine manufacturers to be competitive. Some of the special requirements include classified areas, weather protection, and noise requirements. In addition to supplying packaged gensets, we can assist with noise attenuation of other equipment where location or worker safety require additional protection.

-

Automatic Tube Cleaning Systems / Backflush Systems

Automatic Tube Cleaning Systems are used on shell & tube heat exchangers to enable frequent cleaning of the heat exchanger tubeside (multiple times daily) while the process is still online and the heat exchanger is operating. For applications which the dirty side is not the tubeside or a different style of exchanger is being used, the system will allow backflushing of the heat exchanger without mechanical cleaning. This process should extend the life of the exchanger, enabling longer runs between cleanings.