Compact heat exchangers utilize various plate technologies to reduce the required surface area for heat transfer. These exchangers are generally used for lower pressures, although some welded plate styles can be used for high pressure applications. These generally utilize standard plate sizes, which can make them cost effective.

Compact Heat Exchangers

-

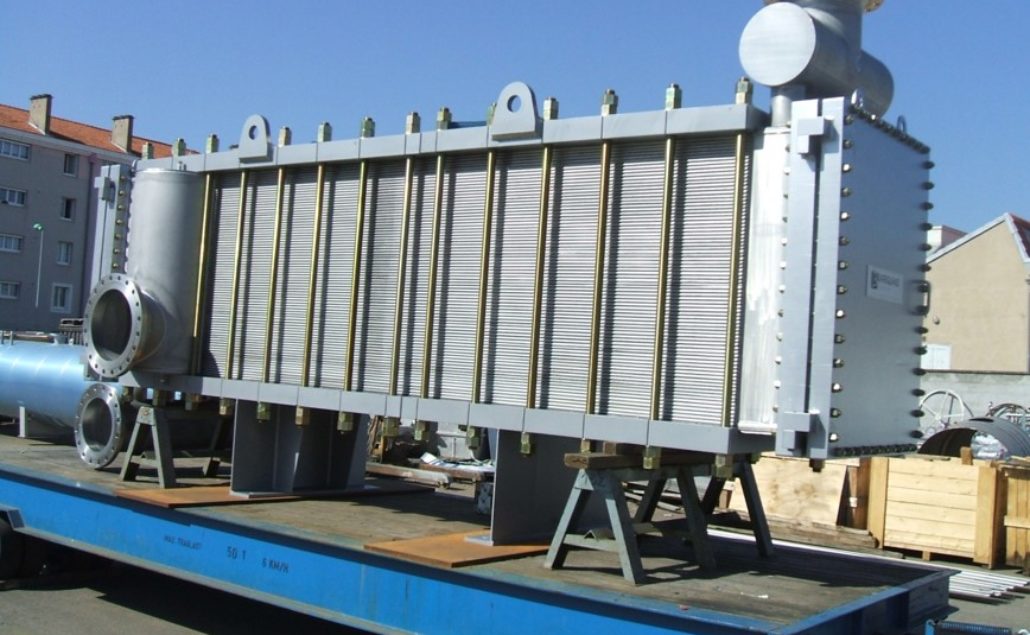

Platular® Heat Exchangers

Platular® heat exchangers are welded plate heat exchangers, which are manufactured with dimpled or studded plates. This allow the unit to be more cleanable than other styles of welded or gasketed plate technologies. Platular® heat exchangers can use various plate materials, including stainless steel, duplex stainless steel, nickel alloys, and others. Design pressures range up to 580 psig and 750 degrees F, depending on plate configuration and size.

-

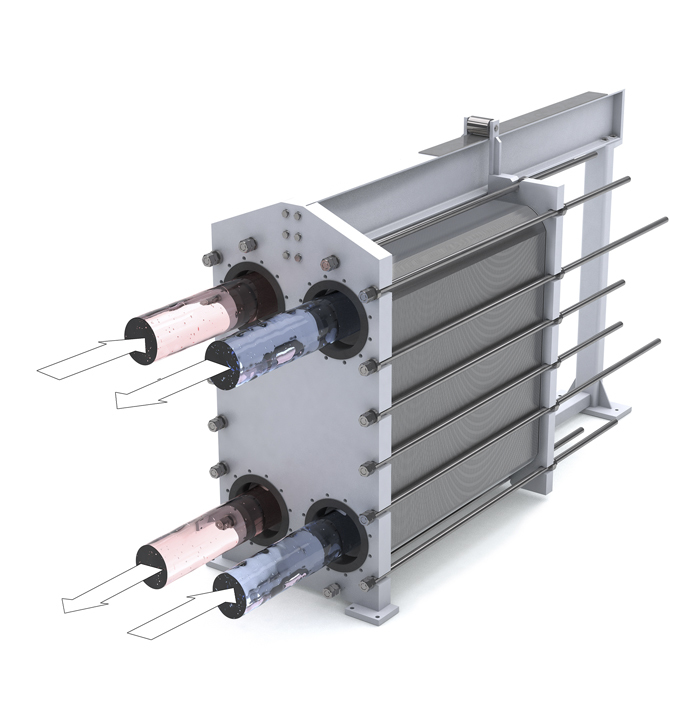

Gasketed Plate Heat Exchangers

Gasketed Plate & Frame heat exchangers are the most cost-effective of the compact heat exchanger models. These exchangers utilize corrugated plates with gaskets on each plate for sealing the fluids. These exchangers can have designs as high as 360 psig and 383 degrees F, depending on plate and gasket materials. Applications for Gasketed Plate & Frame heat exchangers include liquid service and some condensing services.

-

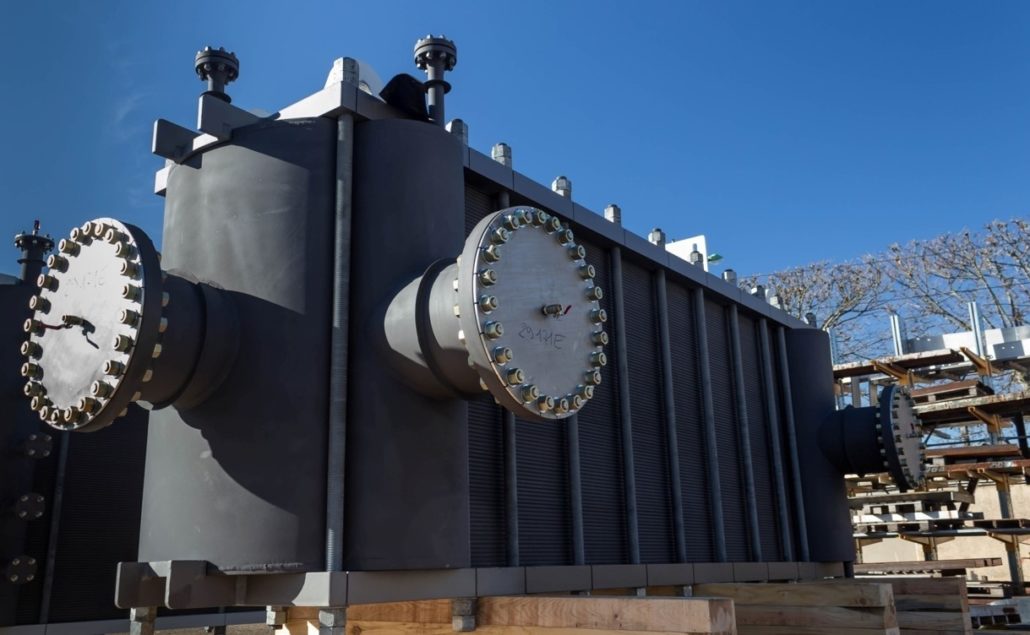

Plate & Shell Heat Exchangers

Plate & Shell heat exchangers utilize circular, welded, corrugated plates. This design enables the Plate & Shell heat exchangers to operate with high design pressures, up to 5,800 psig, depending on plate materials and size. Temperatures up to 932 degrees F are possible as well. Materials of construction for the plates include stainless steel, nickel alloys, titanium, and others. These exchangers can be used for single phase, condensing, and boiling applications.