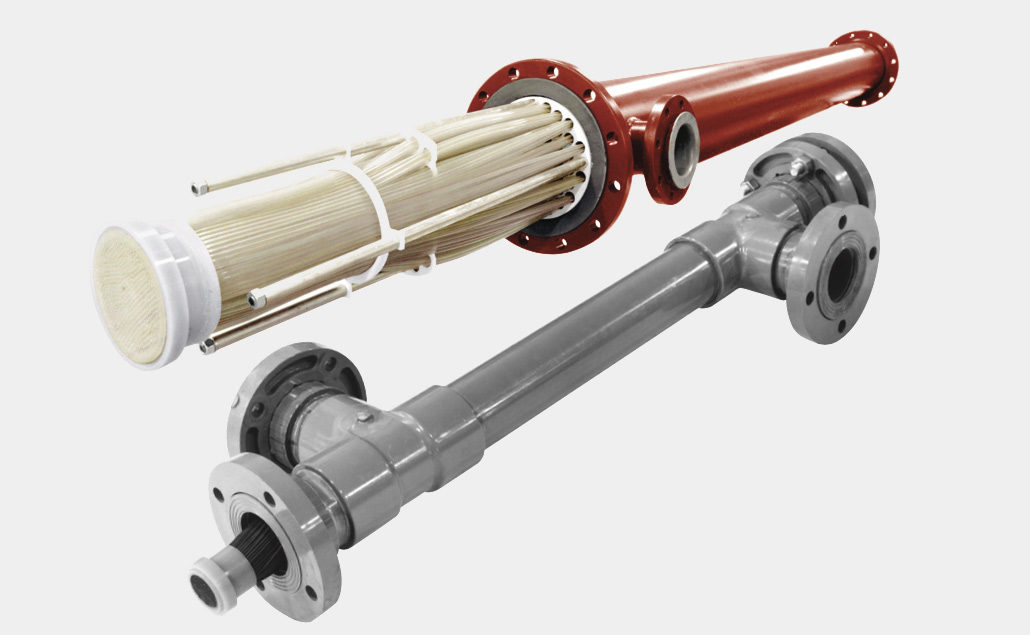

AMETEK is the original manufacturer of fluoropolymer heat exchangers, and uses the highest quality materials for their heat exchangers. In addition to FEP and PFA materials, AMETEK uses a proprietary “Q” tubing Fluorocarbon materials, which improves the thermal efficiency, pressure and temperature capabilities. AMETEK manufactures Fluoropolymer heat exchangers as shell & tube as well as coil designs.

Some industries for which the AMETEK Fluoropolymer heat exchangers are applied are sulfuric acid, nitric acid, hydrochloric acid, hydrofluoric acid, acid recycling / regeneration and metal finishing.

AMETEK’s coils are used for steel pickling, plating, etching and reactor applications which the fluid in a bath is corrosive. These coils, made with Fluoropolymer tubes resist the accelerated fouling which is experienced with these applications. Since these are flexible, they are able to be installed in most tank configurations where rigid metal coils are difficult to install.

Brochures

- PV4 Series Shell & Tube Heat Exchangers

- Shell-and-Tube Heat Exchangers 30-Series Mid-Size (4 inch shell)

- 30-Series 10 Inch Shell-and-Tube, and PV-4 Series 3 Inch Shell-and-Tube Heat Exchangers

- Shell & Tube Heat Exchangers 30-Series Large Capacity Model 900 (14 inch shell)

- Supercoil Models 100, 168, 280 FEP, PFA and Q-Series

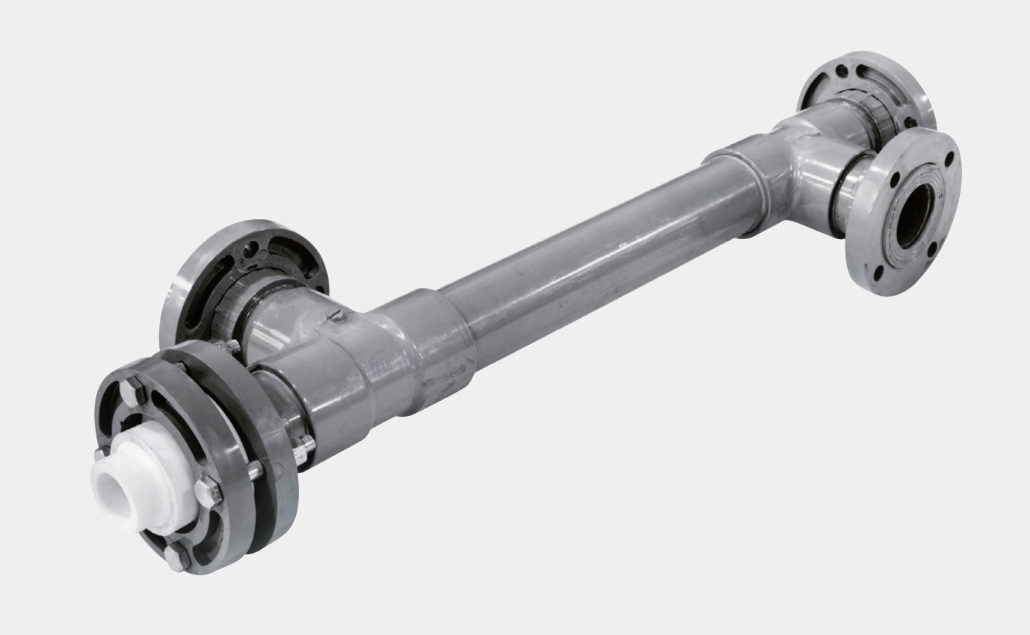

- Slimline CoilTM Model D 500 & QD 500 Heat Exchangers

- Minicoil FEP and Q-Series Heat Exchangers