As the workhorse of the heat transfer industry, tubular heat exchangers have the widest operating temperature, pressure, size and material range. These exchangers separate two fluids, which exchange heat across the tube wall. These tubular heat exchangers come in several configurations including shell & tube heat exchangers, waste heat boilers and waste heat recovery units.

Tubular Heat Exchangers

-

Shell & Tube Heat Exchangers

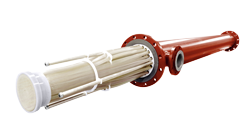

Shell & Tube heat exchangers are tubular heat exchangers in which tubes are installed inside of a pipe shell. One fluid flows inside of the shell while the other fluid flows in the annulus space between the outside of the tubes and the inside of the shell. These heat exchangers can be fabricated from many materials ranging from carbon steel or stainless steel to nickel alloys or titanium. These shell & tube heat exchangers can have design temperatures over 1,000° F and pressures to 10,000 psig.

-

Fluoropolymer Heat Exchangers

Fluoropolymer heat exchangers are used for corrosive applications which the metallurgy which would be required is prohibitively expensive. These exchangers used Fluoropolymer tubes and can be shell & tube heat exchangers or coils.